Welcome to our February 2021 Newsletter. This is the first in a series of monthly newsletters we will send out, each one focusing on a different group of subsystems. This month we focus on Aerodynamics, Business, and Chassis subsystems.

Due to the ongoing COVID pandemic, we are unfortunately stuck working purely online as a team.

Crowdfunding ends SUNDAY NIGHT, February 28th, at 11:59

After so many months spent purely focused on design, we have more projects than ever we cannot wait to make reality when it is safe to do so. With your help we can make our next car be one of the largest steps forward in our history. Click here to learn more and support our team of dedicated and passionate engineering students.

Aerodynamics

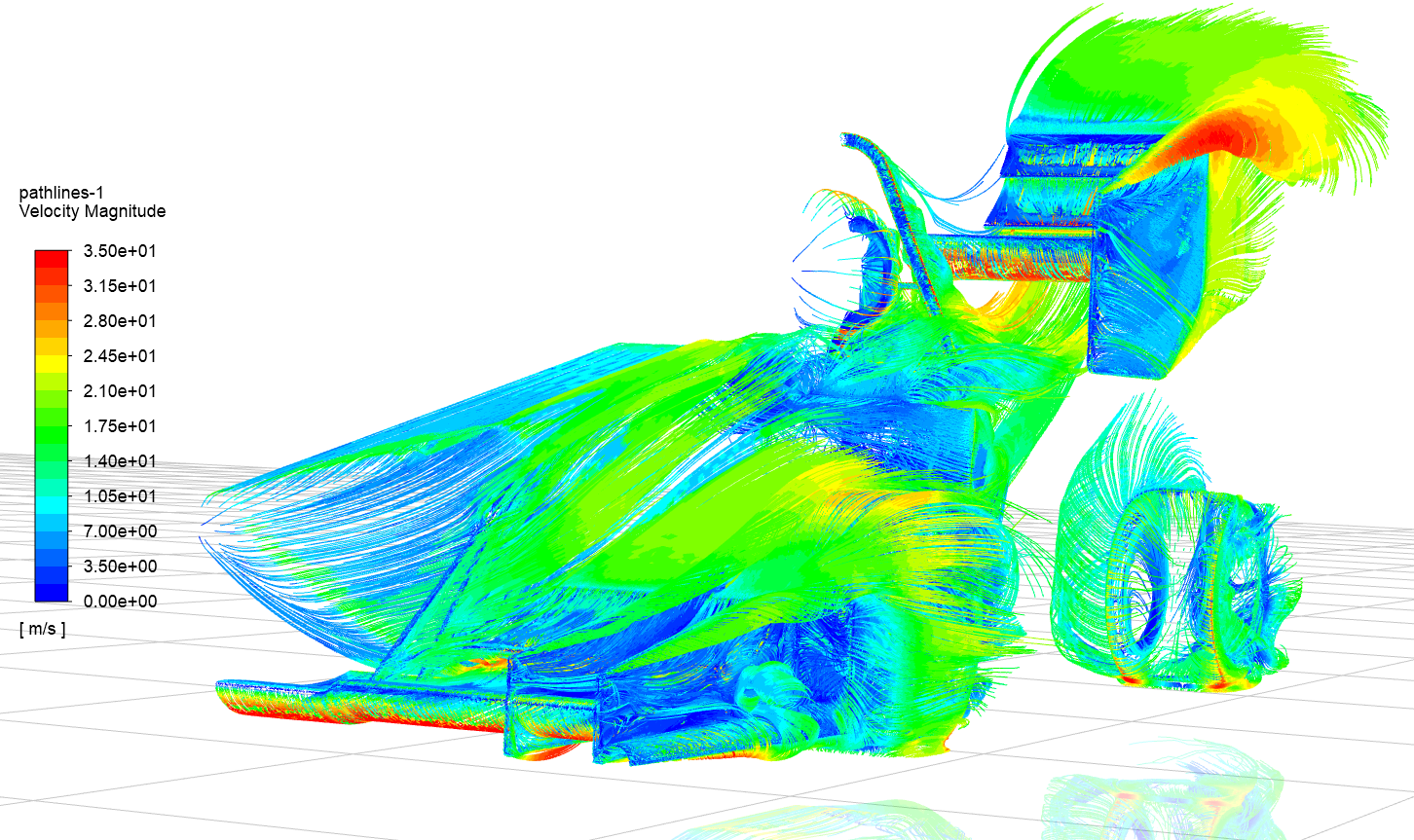

The overarching goal for our next car is to maximize rear downforce, while maintaining a center of pressure specification of 60% set in B19. To accomplish this, aerodynamics has taken a step back in our design and closely studied the effects of full car geometry on various aerodynamic surfaces. A few examples of this include reclining the driver to promote cleaner flow to the rear wing, as well as raising the front floor section to increase airflow underneath the car and to increase front wing center section performance. By increasing mass flow underneath the car, we can use the undertray more effectively and reduce outwash.

We have committed to a new meshing software within Ansys called Fluent Meshing. This may sound familiar as this mesher is now combined with our CFD solver, Fluent, which we have used since Aero’s inception. Using this new mesher in our workflow dramatically reduces CFD simulation setup time, mesh creation time, and solving time, all while increasing mesh resolution.

Finally, we are proud to announce that for the first time in recent memory, all new aero members have been fully introduced to CFD and are actively pursuing their own projects including front wing “element 4” and rear wing biplane. Front wing “element 4” is a low camber inverted winglet that cantilevers off of the chassis near the front pushrod, designed to divert wake from the front wing downwards.

Once these studies are completed, we will resume development on undertray and sidepods as originally planned. Pictured above is a pathline of the full car created in Fluent Solver which we used to qualitatively study the effects of driver position on rear wing performance.

Business

Business has been working hard with traditional business-related tasks, namely our presentation competition and crowdfunding which ends this weekend. Crowdfunding is an optimal way for us to set the team up for a great next manufacturing cycle, especially with how uncertain COVID has made our budget. We’ve also been trying to prepare for next year through some different projects.

We are continuing to push for corporate and material sponsorship, emphasizing the search for a title sponsor. We also realize that material sponsorship is an effective way for us to keep our costs down. In the past couple of months, we have sourced shop towels, safety glasses, calipers, and more. While this pails in comparison to last year’s sourcing engines from KTM or carbon fiber from Sigmatex Material Innovation, anything helps!

The website is looking more beautiful than ever with some new features and a new home page. We’re proud to continue to update it as our team evolves. Check it out if you have time and send us any suggestions! We are also finalizing a new social media plan to keep our audience engaged while we remain a virtual team rather than an in-person one.

Business is going to have our second ever CDR in early April and would love anyone who is interested to attend! We always welcome suggestions. Shoot juliapastis@berkeley.edu an email, and she would love to talk to you. Business wouldn’t be where we are without the strong foundation our alumni and community members built, so thank you!

Chassis

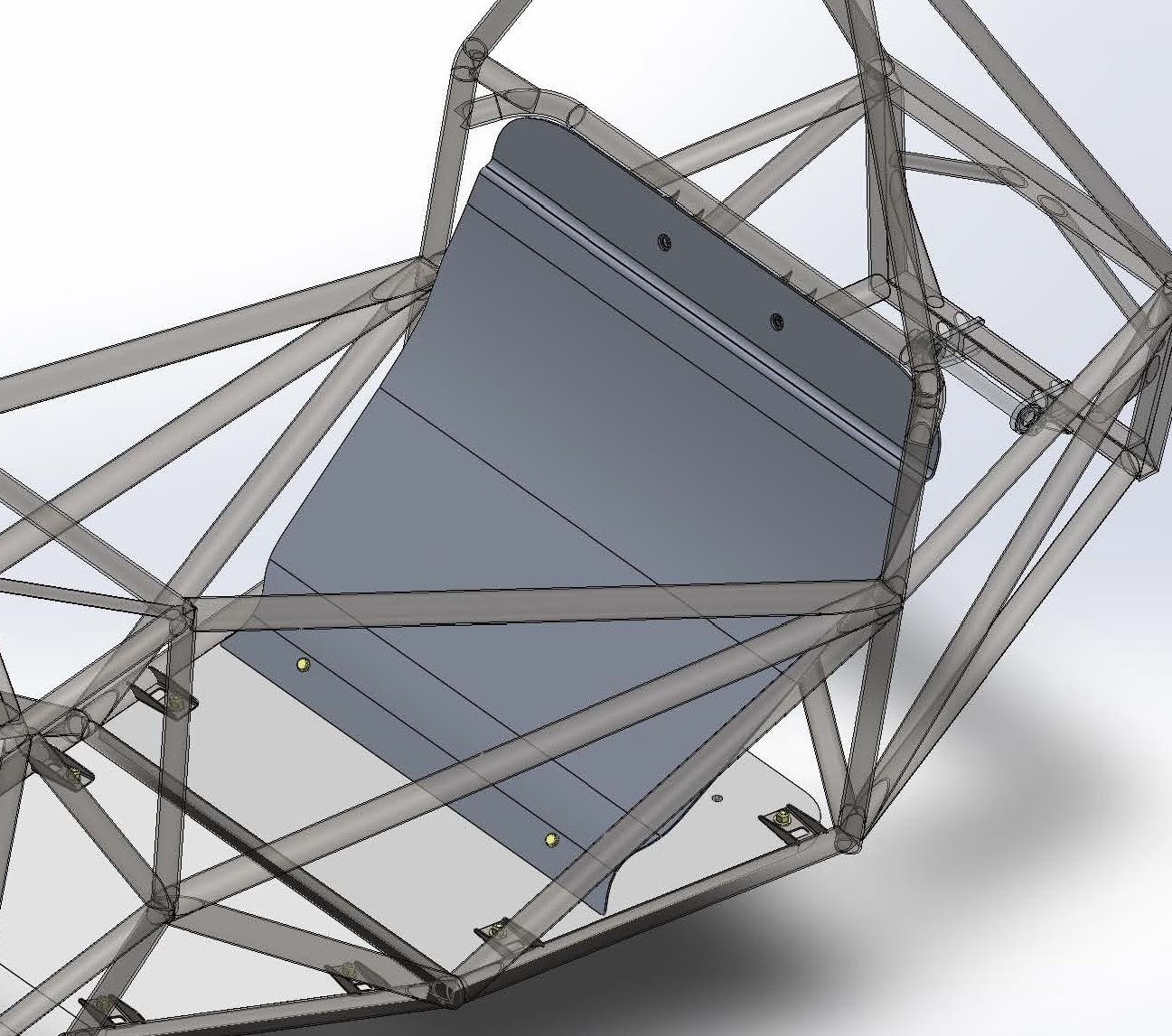

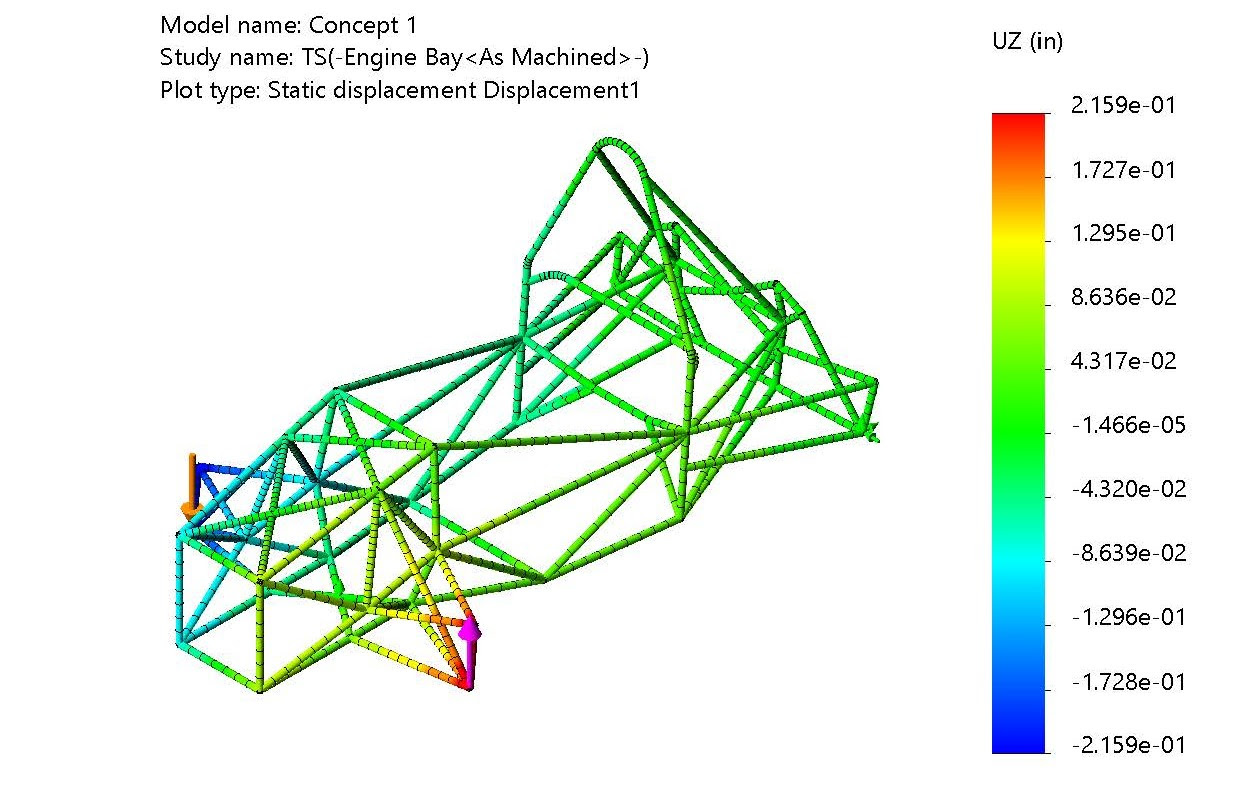

Chassis is benefiting from a large workforce this year, enabling us to diversify our efforts in an effective way. To the upper left, you can see an exploration of a new floor concept we are working on to improve manufacturability and incorporate a new pedal tray design. As we develop new floor designs, we continue to test torsional stiffness and camber compliance simulations. We are also investigating the use of new firewall methods to reduce heat transfer into the cockpit from the engine bay, as well as redesigning the mounting for ease of installation and removal.

Thirdly, we are working to further optimize the front bulkhead support tubes to reduce weight while maintaining our current torsional stiffness specification. Finally, we are also evaluating our next car’s engine mounts by running Ansys static simulations with loads from the piston and chainline.

If you haven’t yet, please consider visiting our crowdfunding page and supporting our community.

If you are an alum and would be willing to let us feature you on social media, contact juliapastis@berkeley.edu. We are hoping to post a collection of alumni’s stories to show how amazing graduates of our team are and share some cool stories.

Thank you again for your support. BFR hopes everyone is doing as well as possible with the current circumstances, and now more than ever appreciates the alumni, sponsors, and community who make this team what it is.

Want to receive the latest updates? Sign up for our mailing list!